One of good substitution of steel grating with many better features than steel ones FRP grating is good for many chemical corrosive applications due to is superior anti corrosive ability and low maintenance feature, which can save quite a lot labor and material cost as well as the risk during the replacement procedure. Meanwhile, light weight and good machinery properties could provide safe walkway or platform in many cases.

Molded fiberglass grating is manufactured by interfacing reinforcing glass fibre roving within a polyester resin, thermally cured in the mould. Grating produced using this technique yield a product having 30-35% (by total weight) of fiberglass reinforcement. For fire retardant protection, the resin used are complete with fire retardant additive to obtain class 1 fire spread rating of 25 or less as per ASTM E-84. UV inhibitors and antioxidant are included into our recipe of gratings to achieve better UV protection.

|

|

|

|

|

|

Features of powercomposites molded grating |

|

|

|

|

|

Chemical Resistanc Non-conductive Light Weight Fire Retardancy Non-Skid & Safety Low Maintenance Easy Installatione Ultra-violet resistant Bi-directional Strength

|

|

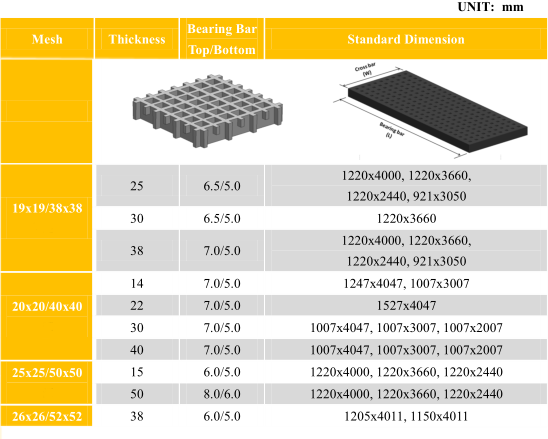

Mini mesh FRP grating

Mini mesh grating provide a ‘middle of the road’ Soultion to those applications where solid flooring is not permission due to airflow requirement, but where the openings must be smaller than our conventional products. Our mini mesh flooring system has one-fourth opening of our standard 38mm square mesh grating. The smaller openings prevent objects as small as 13mm from failing through, and because of the closer spacing of bearing bars. The mini mesh panels can provide an easier flooring for purchasing cart, drum trolley and they comply with ADA(Americans with Disabilities Act of 1990) and DDA(Disability Discrimination Act in UK) requirement for wheelchair floorings. Further, our mini mesh panels meet the 15mm ball test for floorings, a European safety requirement commonly used in some sectors of the offshore industry.